Guillemot has wind beneath its wings

Guillemot can guarantee a flawless supply thanks to its weaving and knitting departments. Its equipment also allows flexibility while respecting the highest quality standards.

The world of weaving is very different from knitting. In a woven fabric, there are threads of weft and warp that crosses each other according to a weaving pattern. The warp threads make up the length of the fabric and are reunited and wound on a « warp beam ». We find the weft wires in the width and they are inserted through the warp by feeders and rapiers. These feeders and rapiers equipped with small clamps allow a very tight control of tensions to produce a regular fabric, compliant to the highest standards and ready to protect you.

Tissage

Tissage knit

knit

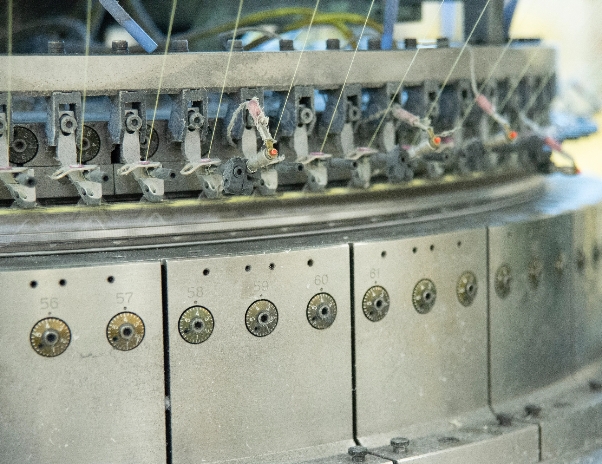

Circular knitting is carried out using individual needles located on a cylinder as well as on a dial placed 90 degrees from the cylinder. Each needle receives the thread delivered by feeders and is activated by cams precisely controlling the tension as well as the required knitting pattern. Several sensors allow continuous verification of the different control points on the machine. As it is circular, it is with each revolution that the loom inserts up to 96 threads at once. The fabric is then rolled up after passing through the illuminated section allowing continuous visual inspection.